Non-Metallic EODD Pumps

Non-Metallic Pumps Built for Real-World Industrial Demands

Cognito Non-Metallic pumps are engineered to thrive in demanding wastewater treatment and chemical transfer environments across commercial, mining, and industrial operations. Leveraging our patented diaphragm design and a virtually maintenance-free electric drive, these pumps significantly extend MTBF, delivering the trusted capabilities of an AODD pump with the added efficiency, service life, and precise control of an electric solution.

![COG.E.PP.3.10.IN.10[B]](https://www.cognitopump.com/hs-fs/hubfs/COG.E.PP.3.10.IN.10%5BB%5D.png?width=1000&height=800&name=COG.E.PP.3.10.IN.10%5BB%5D.png)

76 mm (3") Non-Metallic EODD Pump

51 mm (2") Non-Metallic EODD Pump

38 mm (1.5") Non-Metallic EODD Pump

Protect Your Pump, Process, and People

Use our Chemical Compatibility Tool to help prevent hazardous chemical interactions that can cause equipment failure, leaks, and unsafe operating conditions.

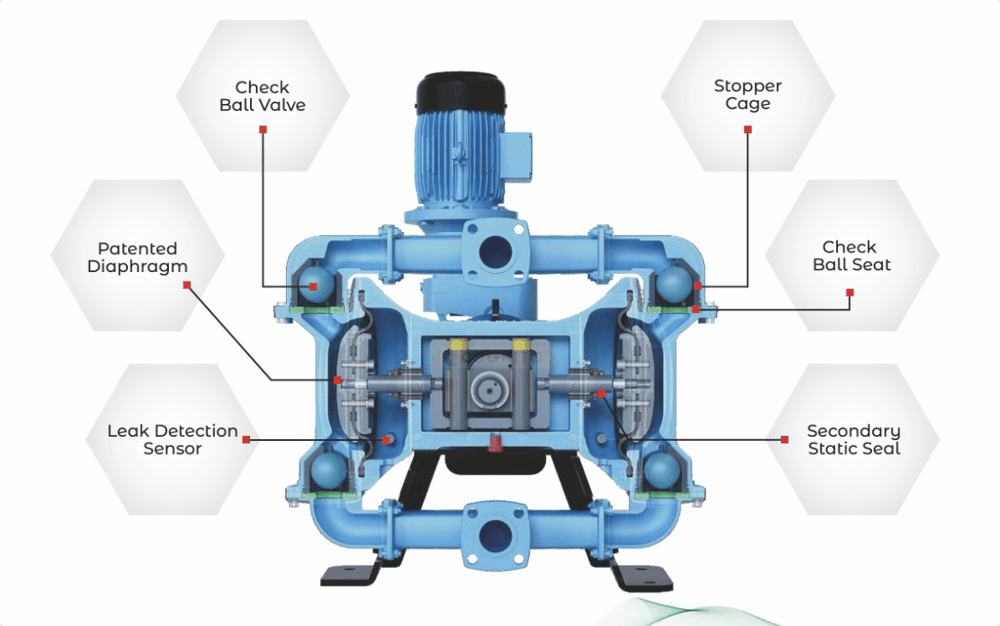

Cognito Features & Benefits (Plastic Pumps)

-

Oversized Diaphragms and Reduced Stroke Length: Enhance diaphragm life.

-

Dual Shaft Seals: Protect the pumping mechanism from harsh process fluids.

-

Leak Detection Probes: Standard to protect both the pump and the process fluid.

-

Horizontal or Vertical Motor Configurations: Reduce the pump's overall envelope size.

-

Available Pulsation Dampeners: Can be incorporated to reduce pulsation, protecting down steam equipment.

Bring Us Your Challenges

We are committed to providing the ideal product to meet your industrial needs with our comprehensive, self-contained systems. Our thoughtfully engineered products and expert teams are here to assist you.

EODD Pump Advantages

Our pumps are efficient and easily monitored to deliver cost savings and peace of mind. They offer:

Higher Energy Efficiency

Swift ROI/Payback

Self-Priming

Sealless Pump

Handling of Solids and Slurries

Mechanical Side Chambers Equipped With Leak Detection

Predictive Maintenance & Remote Monitoring

Low Maintenance Cost

Run Dry Capable

Design Features

Industries We Serve

Our robust and efficient EODD pumps are designed to meet the unique challenges of these industries, ensuring reliable fluid transfer and enhanced productivity. Explore how Cognito can support your industry’s specific needs.

Ceramics

We have in-depth knowledge of slurry/slip and glaze transfer applications and the challenges faced in ceramics manufacturing operations.

Paints, Coating, Dyes & Pigments

Remotely monitor the performance of pumps and predict maintenance in order to avoid leakage and interruption in paint and coating operations.

Pulp, Paper & Packaging

EODD pumps allow you to handle both corrosive fluids and slurry while manufacturing pulp and paper.

Metals & Mining

High-performance EODD pumps withstand the harsh conditions of the metals and mining industry.

Chemical & Specialty Chemical

EODD pumps ensure precise fluid handling and reliable performance in demanding chemical & specialty chemical applications.

Lithium Battery

Cognito offers advanced pumps tailored for the lithium battery industry, providing precise and reliable fluid transfer essential for high-quality battery production.

Oil & Gas

Robust and reliable EODD pumps are designed to handle the demanding fluid transfer needs of the oil and gas industry.

Pharmaceutical

Cognito delivers hygienic and precise pumps for the pharmaceutical industry, ensuring reliable fluid transfer and adherence to stringent safety and quality standards.

Starting the pump when it trips at the end of the batch after the pressure spike shooting above the design limit was a major challenge for us. The Cognito Pump helped us eliminate this and many other issues from our production process, and proved to be a boon for our organization. The pump has had a huge impact on our processes.

International Sanitaryware Company

The absence of a reliable indication or alarm of suction choking was a big pain for us as it led to pumps running in dry condition and rupturing the diaphragm. Cognito EODD pumps solved the problems for us and help us achieve better productivity while keeping the maintenance cost to a minimum.

Leading Tire Manufacturer

The Cognito EODD pump and the innovative engineering by their team helped us maintain line pressure at set value throughout the process. The pressure-speed control system deployed by the team solved multiple issues for us by bringing down higher energy consumption and eliminating critical parts damage.

Leading Sanitaryware Producer

Easy Maintenance

Our pumps are designed for easy maintenance to minimize downtime and maximize productivity. See how simple it is to maintain your EODD pump and keep it running smoothly.

Get Support Now

Your go-to source for in-depth information, technical documentation, and expert insights on our EODD pumps and accessories.