Lithium Battery

EODD Pumps for Abrasive Slurries

Cognito pumps seamlessly handle solids and slurries, making them ideal for the lithium battery industry.

Our lithium battery process pumps can run dry without damage and are quick and easy to service when maintenance is needed. Cognito pumps offer higher energy efficiency, swift ROI for critical applications, and are self-priming, ensuring you’ll have smooth operations even in challenging conditions.

Solved

Cognito pumps address the common challenges the lithium battery industry faces because of their durability, energy efficiency, and advanced monitoring capabilities.

High Energy Costs

Pneumatic technology uses compressed air, which is costly.

Seal Failure or Leakage

Abrasive applications often result in downtime and higher maintenance.

Flow Rate and Pressure Issues

Traditional pumps struggle to deliver consistent discharge pressures and flow rates.

Containment and Safety

Leaks can be hazardous and costly.

Predictive Maintenance

Lack of remote monitoring and predictive maintenance increases risks.

High Maintenance Costs

Frequent maintenance needs drive up costs.

Why Choose EODD Pumps for the Lithium Battery Industry?

Cognito EODD pumps are built to operate for long duty cycles with minimal maintenance. Our pumps feature oversized diaphragms and outer diaphragm plates that protect against damage, delivering excellent displacement and extended service life.

Our pumps are a reliable choice for lithium battery production due to their:

- Seal-less design

- Higher flow rates against the highest discharge pressure

- IoT-enabled technology for predictive maintenance and remote monitoring

Trusted Pumping Solutions for Lithium Battery Production

Our experts are ready to help you find the perfect pump for your needs.

Applications

Cognito pumps excel in critical processes within the lithium battery industry. Here’s how our EODD pumps benefit each application:

Lithium Mining

Active Material (Cathode/Anode) Processing

Battery Cell Manufacturing

Which Pumps are Best for the Lithium Battery Industry?

In the lithium battery industry, 3" and 4" stainless steel pump units are the most commonly chosen due to their required flow rates, ability to handle solids, and the robustness of stainless steel to manage abrasive slurries. These pumps ensure reliable performance and long-lasting durability.

Featured Case Study

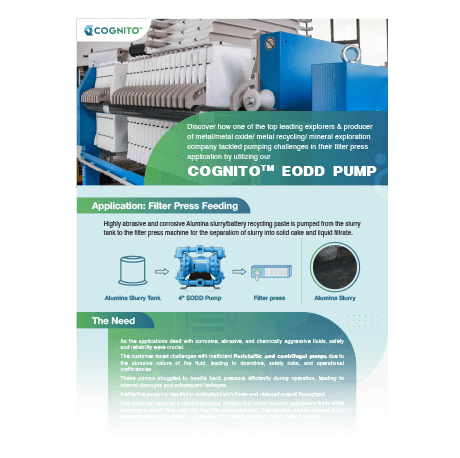

Filter Press Industry Leader Enhances Efficiency with Cognito EODD Pump Integration

Cognito EODD pumps resolve aggressive fluid handling challenges, reducing downtime and improving safety and throughput in filter press operations.

Resources

Your go-to source for in-depth information, technical documentation, and expert insights on our EODD pumps and accessories.

Industrial Pumping Trends to Watch in 2026

Industrial plants are undergoing a fundamental transformation. Across facilities, …

Wastewater Handling Failures Are Costing Corrugated Plants More Than They Realize

In corrugated packaging production, wastewater handling directly affects uptime, s…

Get More From Your Electric Double Diaphragm Pump With Live EODD Pump Training

Knowledge is power, especially when it keeps your operations running without inter…

Make Better and Faster Decisions

Our IoT-enabled electrically operated double diaphragm pumps give you the data you need, wherever you are.